Small capacity biomass firing steam boilers

- Category: Biomass boilers

JSC “GANDRAS ENERGOEFEKTAS” offers boilers and complete plants for biomass with high moisture content (up to 12 % on dry base or 55 % on wet base) burning. It is possible to burn in the boilers animal origin waste, such as chicken manure mixing it with wood chips. To determine possibility of burning one or another king of the waste, manufacturer make test at his factory site, during which delivered from the customer waste is burning, adding to it certain quantity of wood chips. During testing engineers are monitoring the processes inside of the boiler, temperature in the combustion chamber, emissions level and so on, analyzing received information, after what they give recommendations concerning this type of fuel burning, and, if it is required, boiler construction modifications.

Technical data

Thermal capacity – from 348 kW up to 6000 kW.

These boiler can be used for production of:

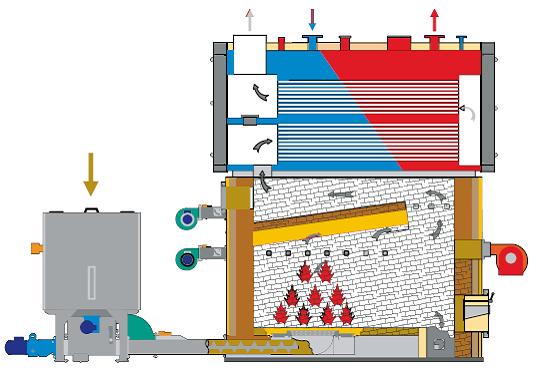

- how water 150°С pressure 16 bar

- saturated steam with pressure up to 25 bar, temperature up to 224°С

- thermal oil up to 320°С

Boiler operation is fully automatic. Automatic control system to be supplied with the boiler.

Burning fuel with humidity up to 50 % on dry base

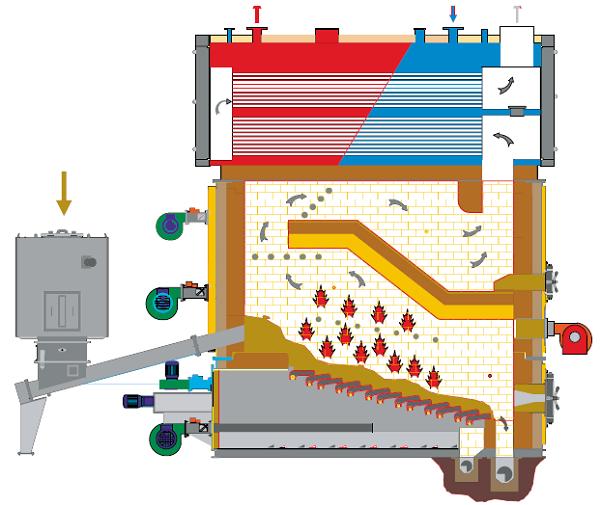

Burning fuel with humidity up to 120 % on dry base

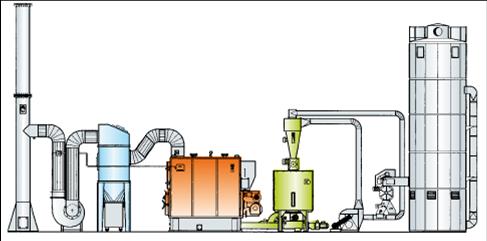

We are ready to offer You complete boiler plant on turn-key basis with all required equipment:

- Vertical or horizontal silos for fuel storage

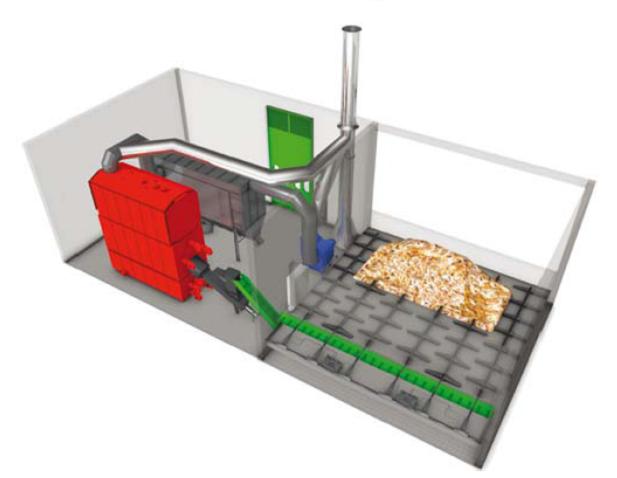

- Moving floors

- Fuel supply to the boiler systems

- Fuel preparing equipment

- Wood wastes, straw crushing lines and others

- Boiler complete with auger burner for fuels with humidity up to 50 % on dry base or complete with moving grate burner for fuels with humidity up to 120 % on dry base

- Under-grate and over-grate automatic ash extraction system

- Automatic burner for gas or oil burning

- Automatic cleaning system

- Economizer,

- Multicyclon (smoke filter),

- Chimney,

- Automatic control system (PLC)

- Remote monitoring system

- Boiler to be supplied preliminary assembled at the factory. Final assembling to be done on installation site and take about 4 weeks (depend on boiler size).

Installation with vertical silos

Installation with horizontal silos with concrete structure and moving floor extractor

Installation with horizontal silos with steel structure and moving floor extractor