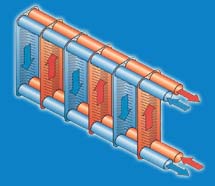

Welded plate heat-exchangers

- Category: High-efficiency tubular heat exchangers

Welded plate heat exchanger consist of a set of plates, lined one after another. The plates are embossed so that an extensive turbulence is created in the flowing media which enhances the heat transfer and prevents creation of sediments.

The main advantage of welded plate heat-exchangers consist of their ability of highly effective transfer of heat, high corrosive resistance (because of welding procedure without intrusion agent), high reliability (excluding all types of sealings), simple assembly and maintenance.

Advantages

-

High corrosive resistance (because of welding procedure without intrusion agent)

-

High reliability (excluding all types of sealings)

-

Simple assembly

-

More compact than shell-and-tube heat-exchanger

Disadvantages High flow resistance as compared to shell-and-tube heat-exchanger

Materials

- Parts in contact with the product: 1.4404/1.4571/1.4306

- Top box: structural steel + varnishing or stainless steel

TECHNICAL DATA

| Measuring units | Execution 1 | Execution 2 | Execution 3 | Execution 4 | Execution 5 | |

| Number of plates | 12-120 | 16-120 | 16-120 | 16-200 | 16-200 | |

| Heat-exchanging surface | m2 | 0,2-2,7 | 2,0-16,5 | 3,0-25,3 | 4,8-60,8 | 7,3-91,6 |

| Max. operating overpressure | bar | 10/25/40 | 10/25/40 | 10/25/40 | 10/25/40 | 10/25/40 |

| Min. operating overpressure | bar | -1 | -1 | -1 | -1 | -1 |

| Max. operating temperature | С | 250 | 250 | 250 | 250 | 250 |

| Min. operating temperature | С | -195 | -195 | -195 | -195 | -195 |

| Max. flow rate (for water) | m3/h | 8,5 | 35 | 35 | 450 | 450 |

| Connection DN/G | mm/” | 25/1″ | 50/2″ | 50/2″ | 150/6″ | 150/6″ |

| Weight | kg | 9-25 | 100-177 | 136-247 | 400-1050 | 500-1310 |