JSC “Gandras Energoefektas” deliver following electric actuators for modulating and on/off duty:

- Multi-turn actuators

- Part-turn actuators

- Thrust actuators

|

Multi-turn actuators

Normally, multi-turn actuators are designed for a travel of 3600 with a range from 2 to 1450 rpm. At this range can be set fault signal systems specifically limit switches and electronic position indicators. Multi-turn actuators mainly used at closed valves, where multi turn action of the actuator transforms into a typical for the closed valve linear movement by means of screwed shaft.

|

|

|

|

.jpg) |

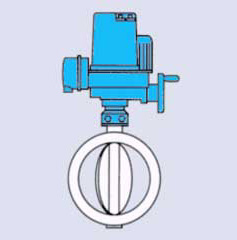

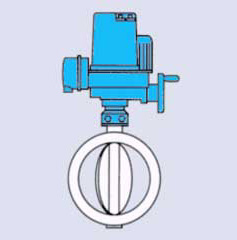

Part-turn actuators

Normally, the internal gear of the part-turn actuator is designed for a travel of 90° or 120°. For this purpose gear ratio is changed. To protect the valve, the output-drive of the actuator is supplied with adjustable mechanical end stops for the final positions. With these end stops travel (90° or 120°) can be changed with setting range ± 5°.

Flanges are standardized according to DIN ISO 5211.

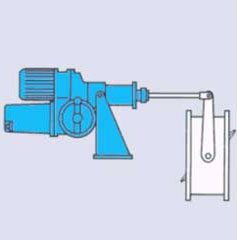

Part-turn actuators, which are installed by means of additional elements, can be supplied by the foot and lever. In this way a connection between valve and actuator can realize leverage with ball joints. Both in motor and in manual operation of actuator, it self-brakes – therefore it can be mounted directly to the valve, for example, gate valve or ball valve without using additional intermediate gear (for example, worm gear, crank gear etc.). For limit switch and fault signal can be installed electric or mechanic control modules. It is possible to install integrated actuator control box.

|

| |

|

|

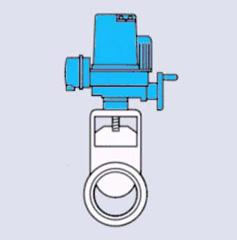

Thrust actuators

Thrust actuators can be fitted to valves which require a linear movement. Thrust actuators transform the torque of a multi-turn actuator into an axial thrust by means of an integrated thrust unit. The required (switch-off) actuating force (thrust and traction) can be adjusted continuously and reproducible. For limit switch and fault signal can be installed electric or mechanic control modules. It is possible to install integrated actuator control box.

|

Actuators characteristics:

Mounting

It is possible to mount and run in any position.

Design features

-

Self-braking of actuator with rotation speed up to 80 rpm (also with a handwheel).

-

Small unit load of a planetary gear, because of constant mesh of teeth.

-

Long life because of life-time lubrication and tightness of oil chamber, ensure no oil decomposition. Module approach.

-

It is possible to fit up and supply additional modules, such as switches, gauges, position indicators, contact devices, control and fault signal systems.

-

Simple changing of the rotation speed by the tooth gear changeover.

-

Full isolation when cathodic protection is required.

Handwheel

Limit switches controlling

Fast and simple limit switches control by means of counting mechanism without contact rollers uncoupling.

Travel adjustment

Additional gauges and mechanical indicator control accounting any travel with a small step, general control reducing gear.

Protection class

Operation without any problem at environment extreme conditions because of protection index – up to IP 68.

.jpg)