Dry cooling towers

- Category: Cooling towers

JSC «GANDRAS ENERGOEFEKTAS» select and supply dry (closed circuit) cooling towers.

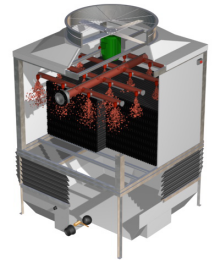

Dry cooler (dry cooling tower) – heat exchanger, which provides cooling of a heat-transfer liquid flowing into it. Because of ambient air exhausted with axial fans circulation through the plates cooling is realized. Technological process requiring a large volume of cold water provided by coolers.

They are also provides cooling of the heat-transfer agent, cooling condenser of the water cooled machines and cooling of the heat engine in power generating aggregates. When water predetermined temperature permanently higher than ambient air temperature dry cooler can work whole year providing electric power economy greater than water cooled chiller. In case of water with lower temperature than ambient air temperature (summer time) is necessary the dry cooler may be completed with an adiabatic cooling system.

Dry coolers designed for open-air installation, therefore additions in liquid with glycol, antifreeze, alcohol etc. use to prevent freezing of the water inside the cooling tower in a cold season.

There are some advantages and disadvantages using dry coolers:

-

There is no evaporation of cold water (evaporation of a wet cooling towers reaches 5% of recirculated water volume per hour). Coolers work in a closed loop, therefore it’s not necessary to add in system cooling water, except cases when occurs tie-down flowing or utility changes;

-

It’s not necessary to change heat-transfer agent circulating in a cooling tower;

-

Liquid is chemically active (antifreeze, glycol, alcohol solutions), but has a very high cost and can injury the environment if it will overflow является.

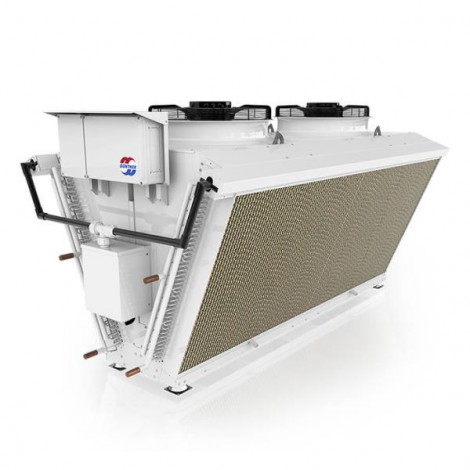

Heat exchanger aggregates for dry collers can be made for vertical and horizontal installation of dry coolers. Also V-type coolers are presented. Each of them can be delivered with one of 4 fans execution according to noise (normal, low, quiet, superquiet).

To save the heat exchanger made from copper pipes with aluminium finning metal plate is used.

Case and foot made from strong zinc-plated steel, covered with powder enamel.

Frame structure provides handling and transportation of dry cooling towers, including a big sized, without any risk.

|

Plane coolers with axial fans. 87 models are available Capacity - 11-927 kW. |

|

One-tier V-type aggregates with axial fans 32 models are available. Capacity - 35-584 kW. |

|

Double-tier V-type aggregates with axial fans 42 models are available. Capacity - 135-1384 kW. |

Operating principle

Operating principle