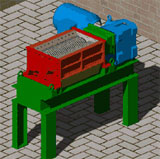

Wastes utilization grinder

- Category: Mixers and Grinders

|

Heavy duty, twin shaft, low speed, high torque grinder and remains one of the most effective solid grinders for bulk reduction, material reclamation and profit from waste. Body: Cast iron. Shafts: High specification alloy steel or stainless steel options designed to suit particular duties are available. Cutters & Spacers: Chromium/molybdenum steel. Base frame: A heavy duty fabricated steel structure suitably strengthened to prevent twisting during machine stall condition.

Drive: Integral motor/gearbox speed reducer type, close coupled to the main grinder module by a solid steel coupling.

Design Features: Cutter Shafts: On the larger unit, each cutter shaft is independently driven by a gearbox mounted at opposite ends of the machine. With independent shaft drives, transfer gears or chains are eliminated and power transmission is direct in line from gearbox to the shaft via a heavy-duty coupling.

Cutter Chamber: The cutter chamber and gearboxes are independently mounted on a heavy fabricated steel structural base frame creating both a much stronger machine construction and allowing easier access to individual parts. |