Vane pumps

- Category: PUMPS

|

Technical data

Pump execution:

|

|

Variable flow pumps are specifically designed for systems or processes where infinitely variable flow from 0-100% of the rated pumps capacity is required. This achieves with a variety of Control Types, without the need for speed variation devices, bypass lines/loops or control valves. Our patented Constant Pressure Control (CPC) pump will operate against a closed valve. This pumps are suitable for the following liquids: almost any viscous liquid, lubricating oils, lube oil additive, residual (black) fuel oils, distillate (white) fuel oils, grease, bitumen, asphalt, polymers, polyols, resin, varnish, glue, edible oil, oily water (bilge), molasses, fats, emulsions, paint (oil bases), soap stock, inks, acetate dope. |

API 676 and other specifications: Rotary pumps can be supplied in accordance with the requirements of API 676.

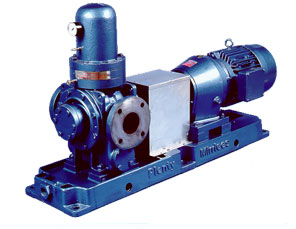

Aggregation: Pumps can be supplied bare shaft or fully assembled with driver on a base plate with coupling and guard. By the Customer request we can deliver pressure snubbers for pumps.

Non standard pumps: Pumps can be factory modified for extremely viscous or arduous applications. Materials of construction are selected according to fluid nature.

Pump sealing: Pumps can be supplied with single or double component or cartridge style seals. Soft gland packing is also available.

Relief valve: Pump has a built-in full flow relief valve for pump protection, as standard.

- Pump manual control

- Chamber of constant pressure

- Electric, pneumatic actuators

|

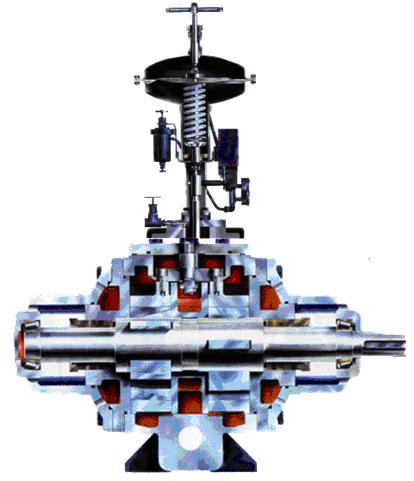

Manual control pumps Manual Control Pumps use a hand wheel to control the flow between 0 - 100% of the pumps capacity. This is achieved by manually rotating the hand wheel. |

|

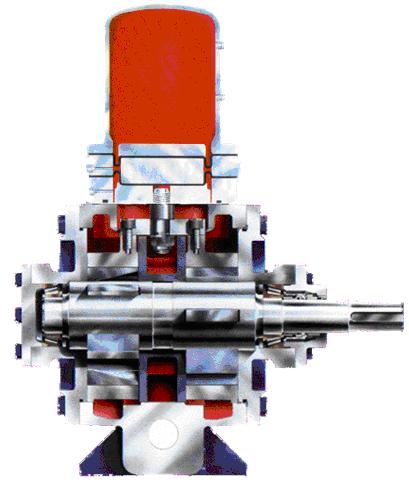

Constant pressure control pumps It is a mechanism which automatically alters the eccentricity of the rotors to the shaft to match the flow rate of the pump to that possible in the system to maintain the set pressure. This construction pumps have their inner bodies connected to the control piston via the bridge. The control piston is enclosed in a cylinder. Gas pressure is applied to the top of the control piston and the delivery pressure of the pump is fed to the underside of the control piston. |

|

Pumps with electric, pneumatic actuators Remote control pumps have their inner bodies connected to an actuator (electromechanical, electro-pneumatic, or pneumatic). Flow control between zero and maximum and reverse between maximum and zero is achieved by the actuator receiving a signal from an external source and moving accordingly. Movement of the actuator changes the position of the inner bodies, altering the eccentricity of the rotors to the shaft, thereby changing the flow rate. Also we can design pump construction which allow changing the transferring liquid direction – pump can pump in both ways. It is very convenient for working in oil storage when it is necessary to pump from one reservoir to another. |

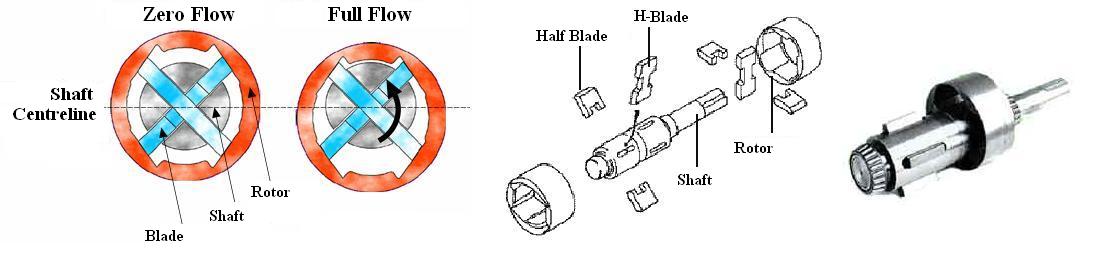

Pumping principle

Pump body has from both heads two built-in pumping sections which are connected to a shaft. Each section consisting one “H” blade and two half blades sliding 90° apart.