Steam turbines

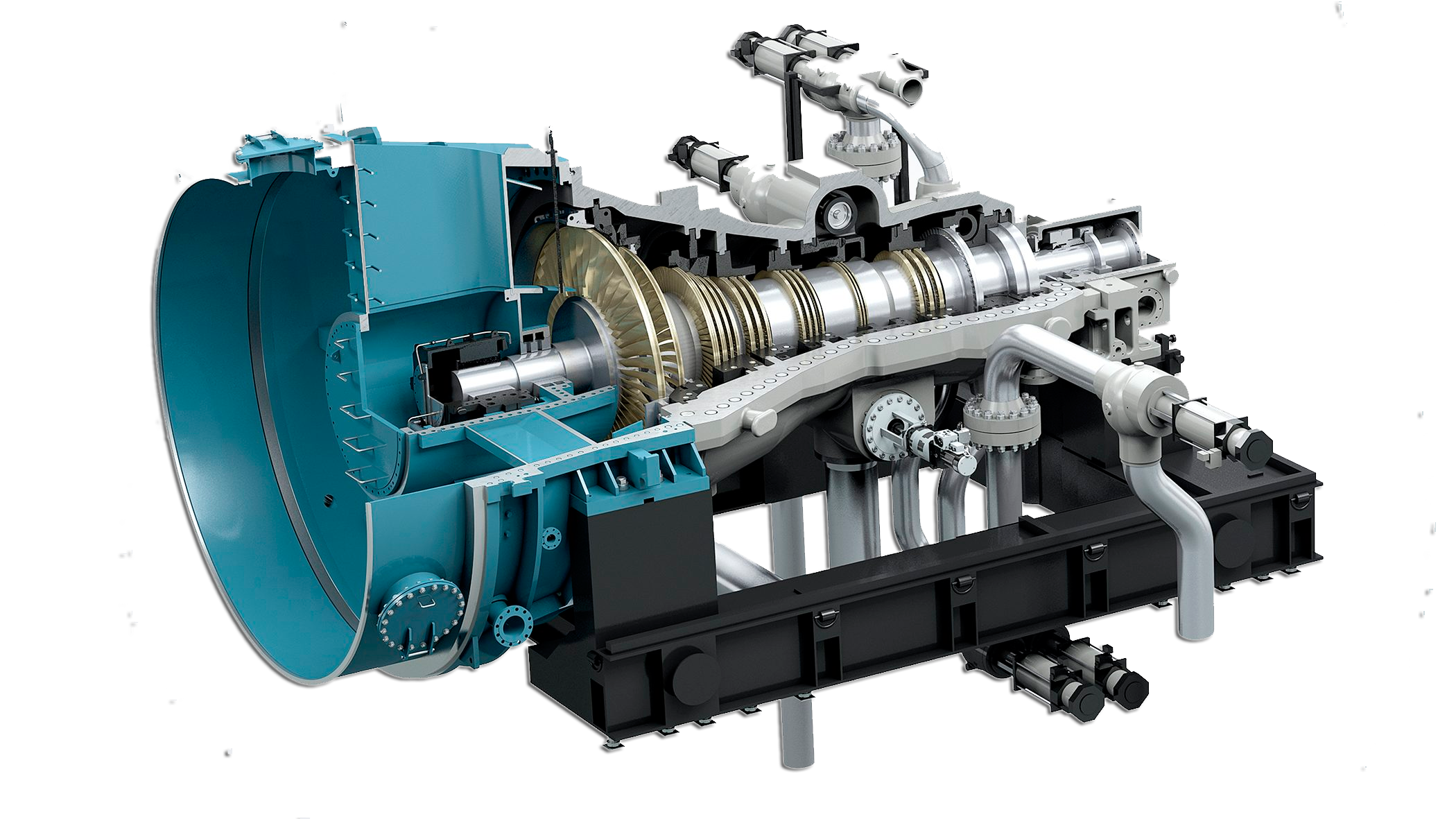

Steam turbine operation principle is: produced in steam boiler steam flows to the steam turbine blades. Turbine rotates and produces mechanical energy, which is used by generator. Generator generates electricity.

Steam turbines electrical power depends on a pressure drop between inlet and outlet steam. Common efficiency (electricity + heat) of the steam turbines reaches up to 85 % in anticipation of unit of used fuel.

JSC “Gandras Energoefektas” provide a service of backpressure (exhaust steam pressure from turbine up to 0.7 bar a) and also condensing (exhaust steam pressure from turbine less 0.7 bar a) steam turbine selection and supplying.

STG could be included to a boiler house, where the steam is used for thermalclamping and technological applications, flow diagram. Thereby, it is possible to get independent from energy system domestic and industrial power consumption resource with minimal investment. Boiler house will turn into mini thermoelectric power station.

With all this steam turbine must work in parallel with power supply system or other electricity source, and in case of damage in power supply system, STG must automatically switch to autonomous operating regime, and after damage will be eliminated, STG must automatically restore parallel operating regime. Steam, used in turbine, then is used for thermalclamping and technological application.

The main advantages of our offered steam turbines (manufacturers: Germany, Italy, Russia, Ukraine):

- The wide range of different turbines type: condensing, backpressure, with low, medium and high parameters steam extraction.

- Our offered steam turbines construction allows to use energy of steam at low parameters – pressure 13 bar a, saturation temperature, which, as a rule, is supplied to reducing units. Such steam usually is produced in boiler plants operated on biomass.

- Up to 5 MW Steam turbine it’s an automatized aggregate, which all main elements and auxiliary systems are mounted on the common baseframe (in steam turbine with capacity above 5 MW all elements also are mounted on common baseframe excluding alternator). STG includes steam turbine, reduction gear, alternator, regulation and automation system, oil system, power frame. Comparatively small dimensions allow installing steam turbine in the small areas and on the low foundation; it could be used free area in the boiler houses or in other production buildings.

The main advantage of steam turbine is jet control of the steam flow – possibility to operate turbine in winter conditions, when turbine has 100 % load, and in summer conditions, when heat load is reduced up to 10 %. - All turbines, including condensing, could be supplied with upward or downward steam exhaust (depend on Customer’s requirements). Upward exhaust allows essentially reducing volume of erection and projecting works comparing with downward or axial steam exhaust turbine – the savings amount up to 800 %; at the same time it is not required to lift up high crane runways - the savings amount of turbine building framework and crane runways erection will be up to 200 %.

- Our steam turbines are heavy-duty design – turbine mantain a good performance level after long time of operation (efficiency doesn’t go down). At the contract signing stage, under customer’s request, it is possible to specify (agree) not limited number of turbine’s start-up and stops (at the same time turbine operating time till overhall and general lifetime will not be reduced). Turbines have NATO AQAP-110 certificate (highest quality standard of machinery for using in NATO armed forces designing and producing), or technical specifications submitted with Russian Federation Navy, this means reliability, highest quality and operation simplicity.

- Common oil system for oil supply to control and lubrication, built-in baseplate oil tank and oil pipelines length’s reducing till minimum possible value allow to reduce used at the plant oil volume. This will make easier submitting process with fire-fighting institution at the project preparation stage, erection and operation, and several times will decrease risk of oil leakages and ignition. Also this construction eliminate necessity of oil pipelines erection / installation, which must be of stainless steel (high price) or phosphatized (dirty, harmful (unhealfy) work, which requires additional costs for fulfillment).

- Steam turbine recourses till overhaul is up to 120000 hours. STG service life – up to 40 years.

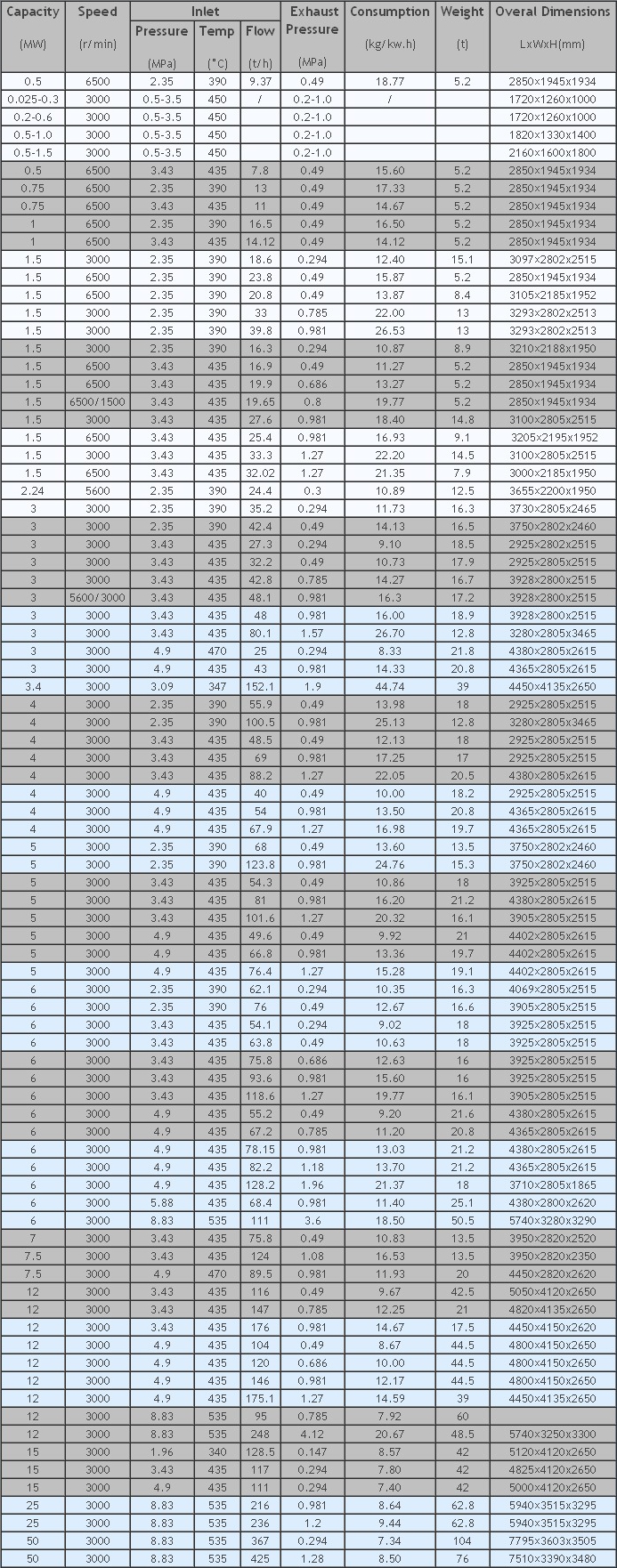

| Main steam turbine parameters | |

| Nominal power | 0,4 - 35 MW |

| Live steam pressure | 8 - 120 bar abs. |

| Process extraction range | upon Customer’s request |

| Exhaust steam pressure | 0,13 - 25 bar abs. |

Company “Gandras Energoefektas” offers full services complex of equipment installation at the Customer’s site: design / projecting recommendations, installation, assembling, start-up works, trial operation, personal training.

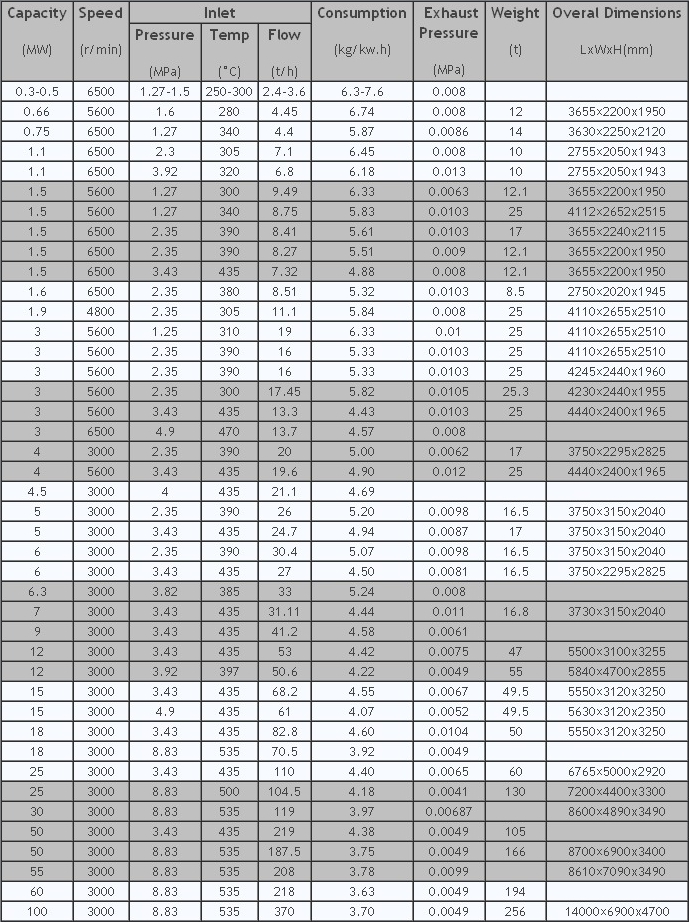

Condensing Steam Turbines

Back Pressure Steam Turbines