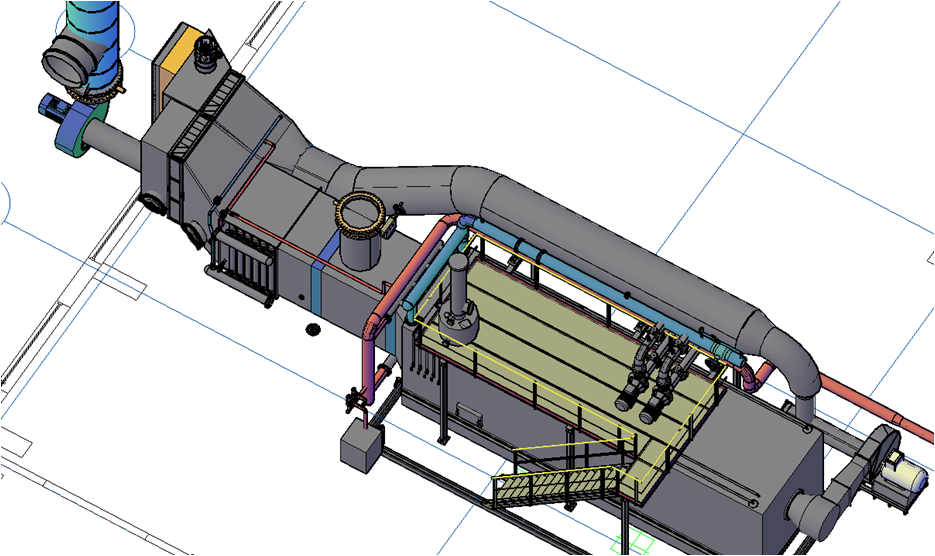

Gas fired flue gas condensing economizer

- Category: Economizers & Scrubbers

|

Part 1. Condensing economizer

|

|

|

|

The condensing economizer works if the temperature of the cooling water is less than or equal to 50 ° C (If the temperature is higher, then condensation of flue gases does not occur in the economizer, which greatly reduces its efficiency.) Working with gas condensate, which is a weakly acidic medium, dictates the choice of material: stainless steel AISI-316. The presence of condensate (which must not be discharged into the sewer) implies the presence of a neutralization system. If the customer wish to clean the condensate and return it to the network as the make-up water, then our company also can offer this solution.

The efficiency of the boiler system and the condensing economizer depends on temperature of the cooling water so as of the flue gases and can reach 102% (when the economizer is cooled with return heating water with a temperature not higher than 44 ° C). |

|

Part 2. Rotary economizer

|

|

|

|

Installation of a rotary economizer for heating combustion air taken from the street by flue gases after the condensing economizer. The casing and cladding must be made with materials that are resistant to flue gas condensation.

Installation of a rotary economizer together with a condensing one can increase the efficiency of a gas boiler up to 105% and reduce the reduction of NOx emissions to 50 mg / Nm3.

The rotary economizer cannot work if the flue gas temperature is above 70 ° C |

|

Economizer characteristics (on example of Daugavpils project):

|

|

|

|

|